|

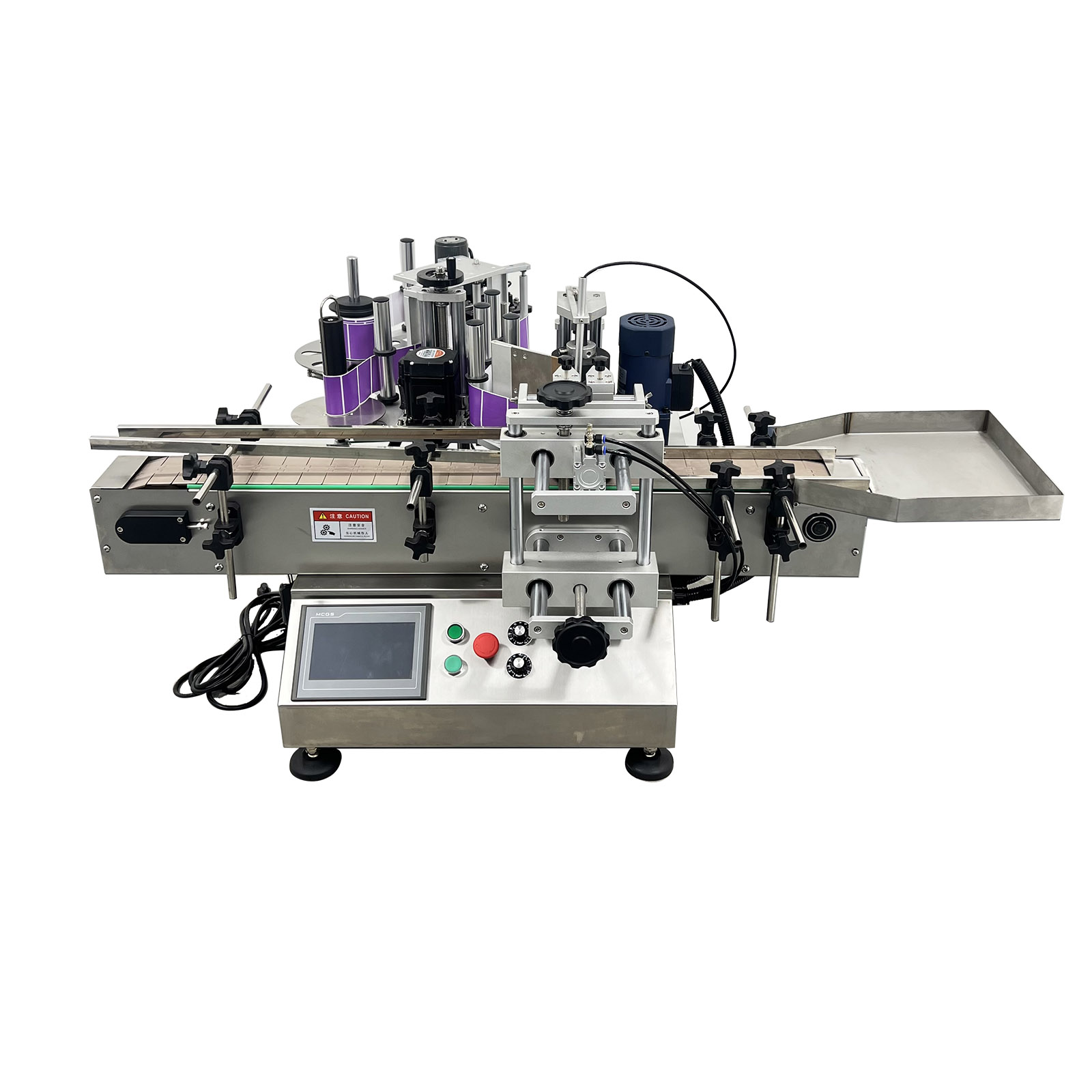

LT-150 Fully Automatic Desktop Chain Plate Conveyor Round Bottle Fixed Point High Speed Coding and Labeling Machine |

|||||||||||||||||||||||||||||

|

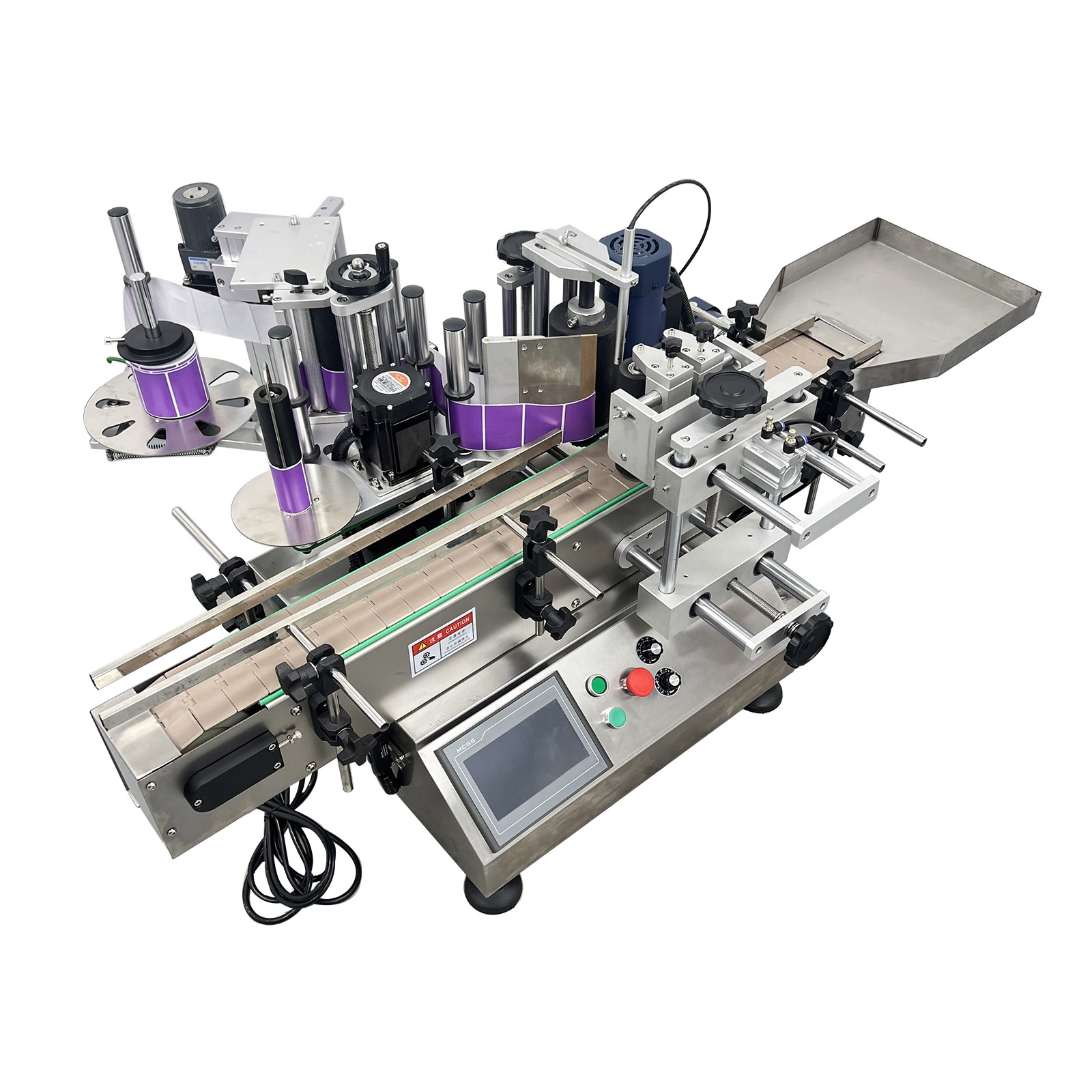

The machine is beautiful, smart, and has a high qualification rate. It is suitable for labeling and coding in cosmetics, beverages, medicine, food, general merchandise and other industries. |

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

| Product parameter: | |||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

| Product Analysis: | |||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

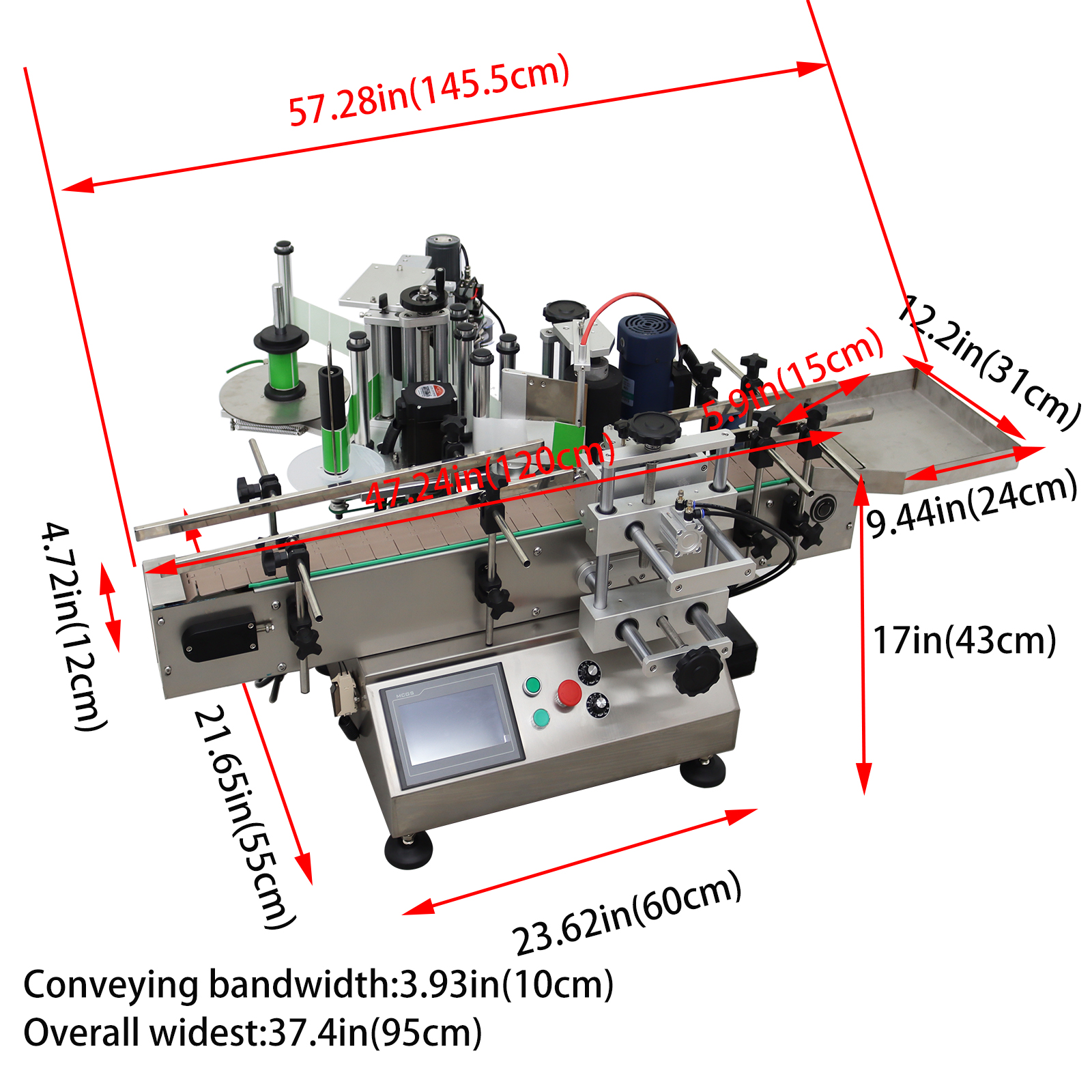

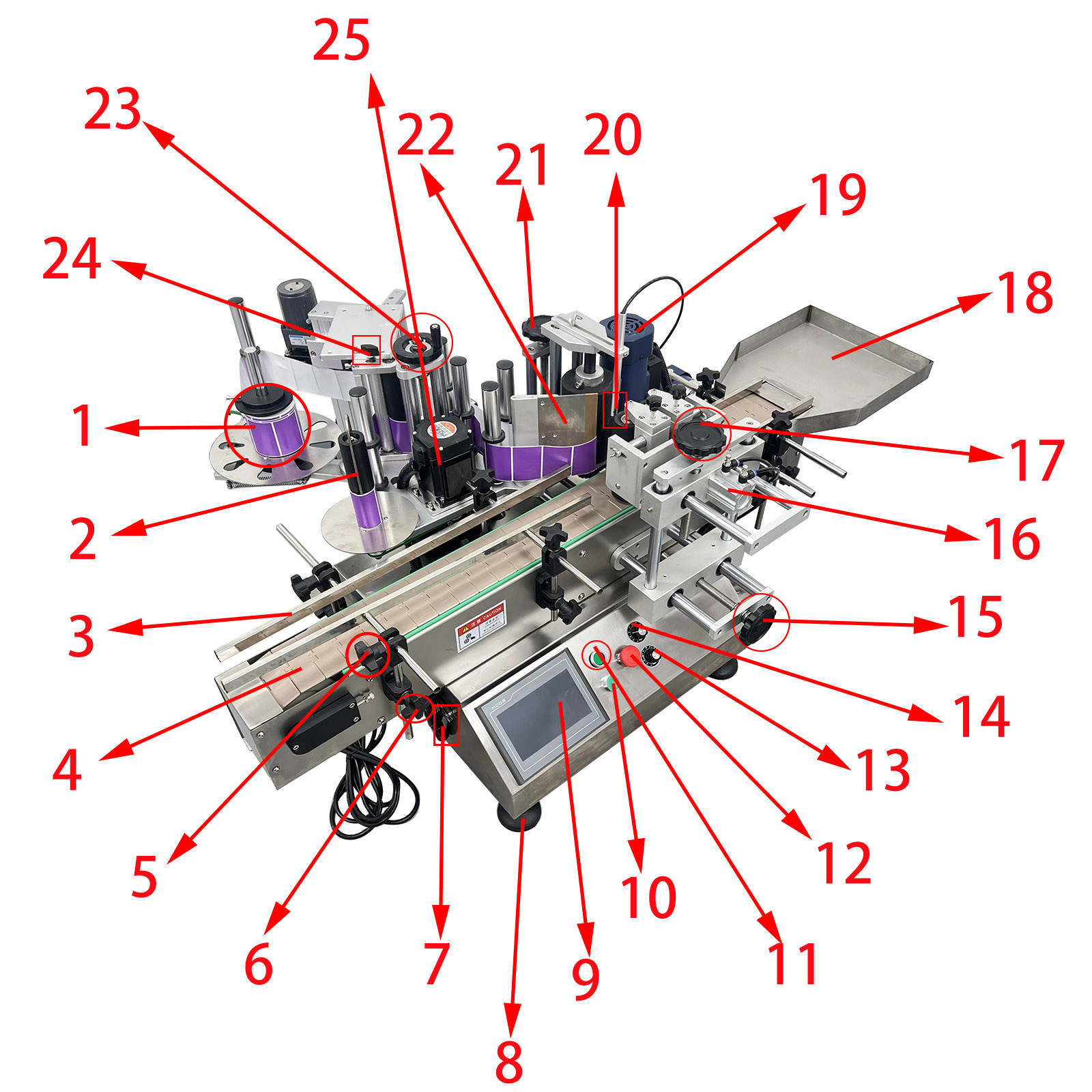

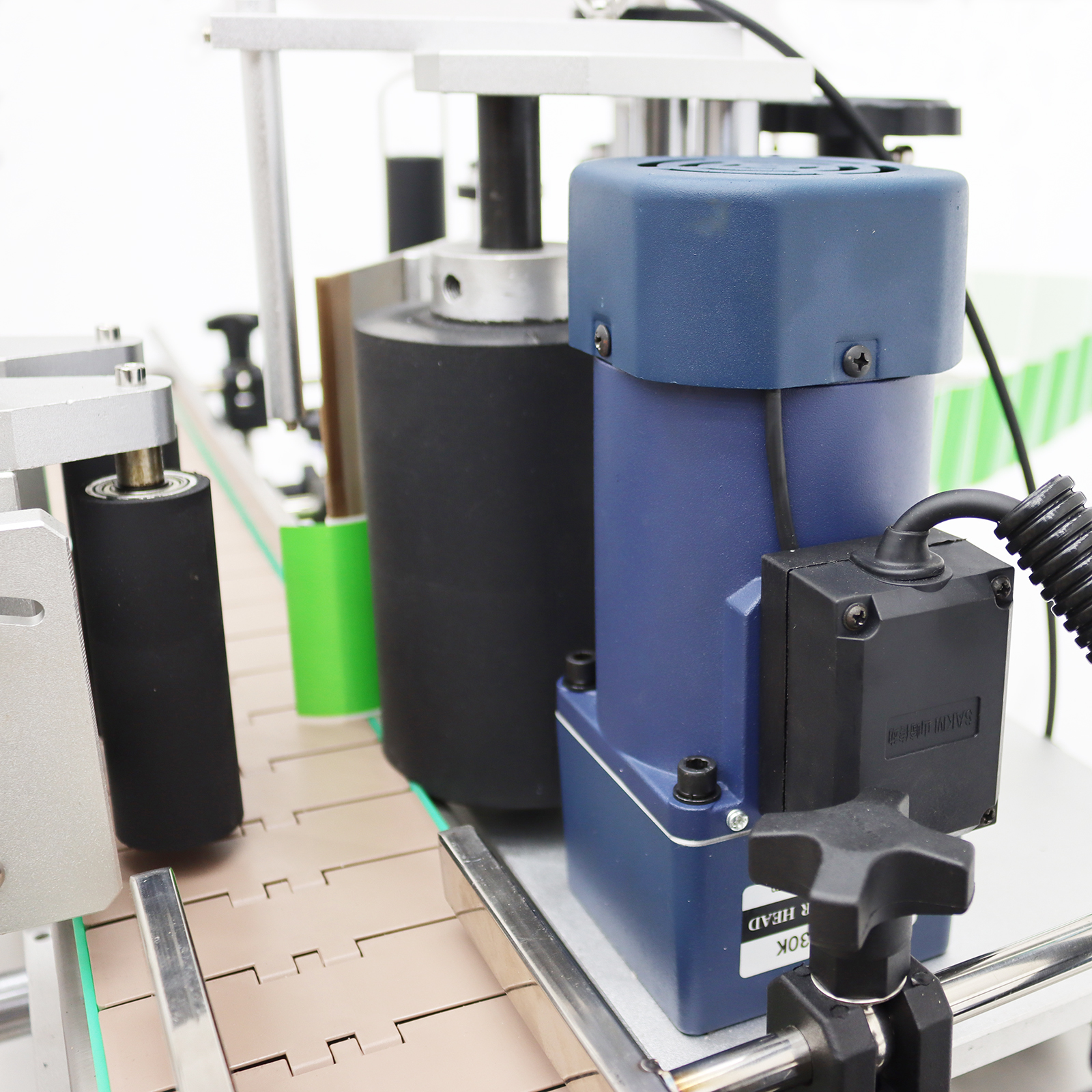

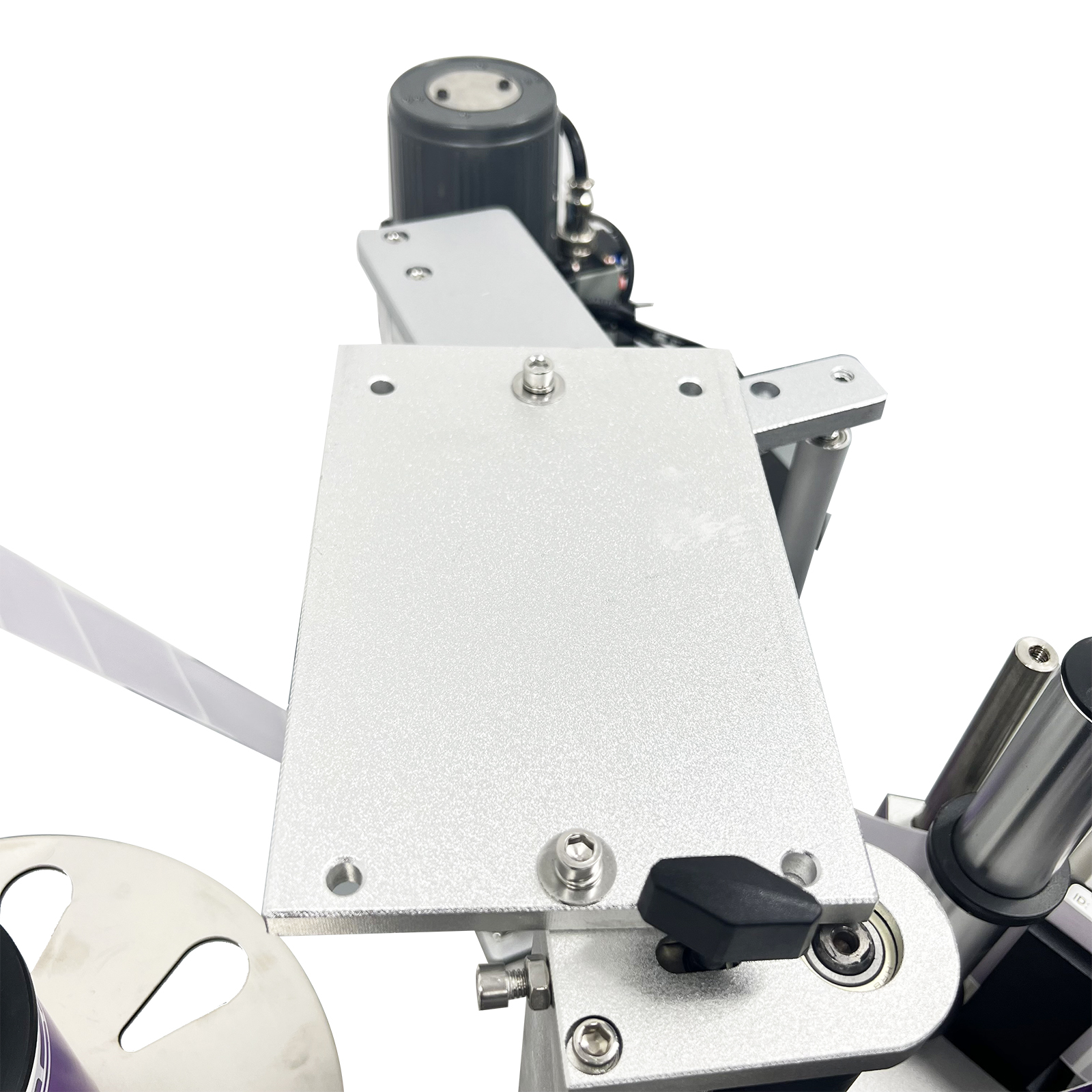

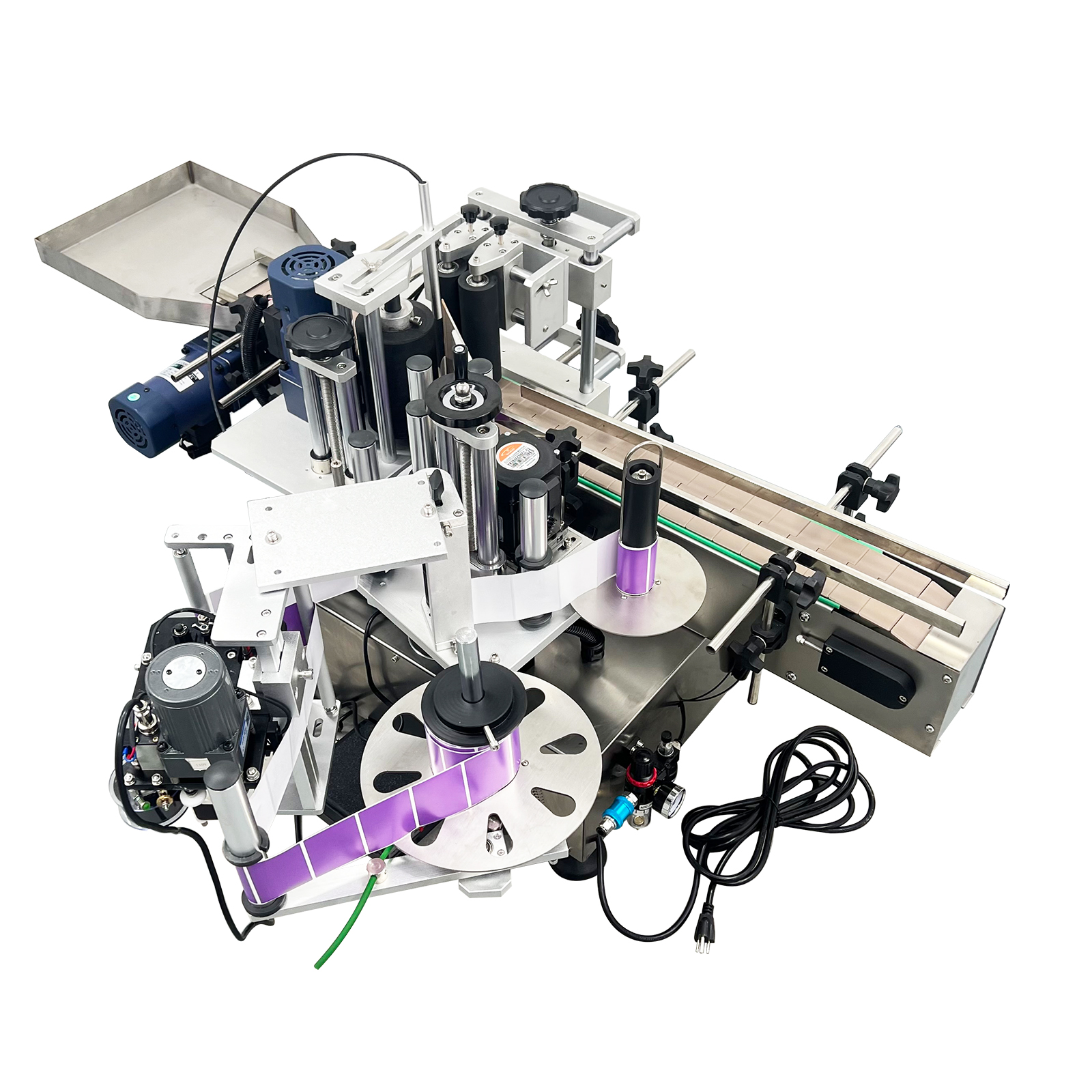

1. Label plate 2. Signing wheel 3. Guardrail 4. Conveyor belt 5. Adjusting knob for guardrail width 6. Height adjustment knob for guardrail 7. Fiber optic amplifier 8. Lifting and lowering the foundation 9. Touch screen 10. Start switch 11. Power switch 12. Emergency stop switch 13. Conveyor Belt Governor 14. Spoke speed regulator 15. Wheel spoke distance adjustment handle 16. Bottle fixing cylinder 17. Spoke lifting adjustment handle 18. Receiving tray 19. Spoke motor 20. Detection of bottle photoelectricity 21. Spoke lifting adjustment handle 2 22. Pull the rubber plate 23. Head lifting handle 24.Clamp label axis handle |

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

| Feature: | |||||||||||||||||||||||||||||

|

|

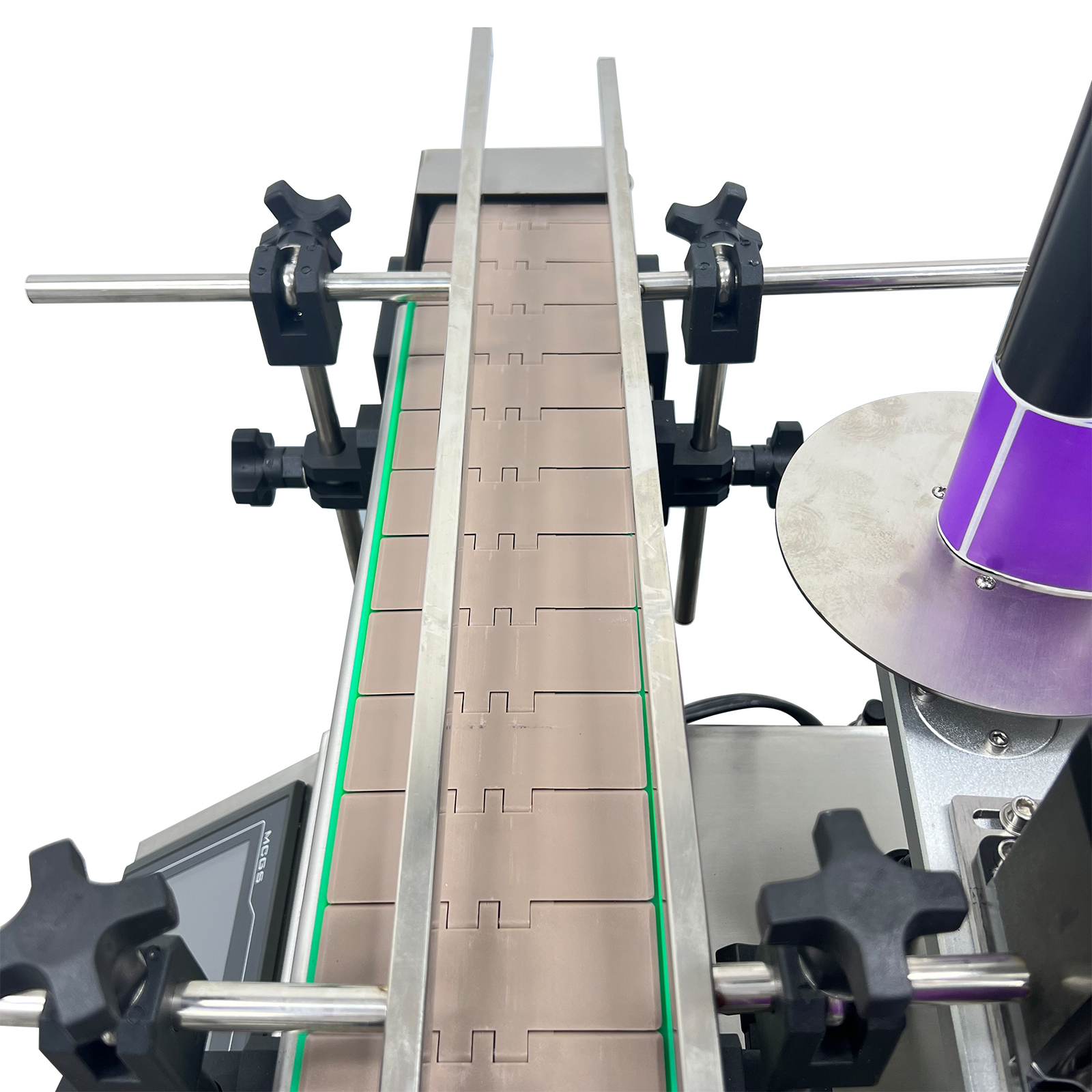

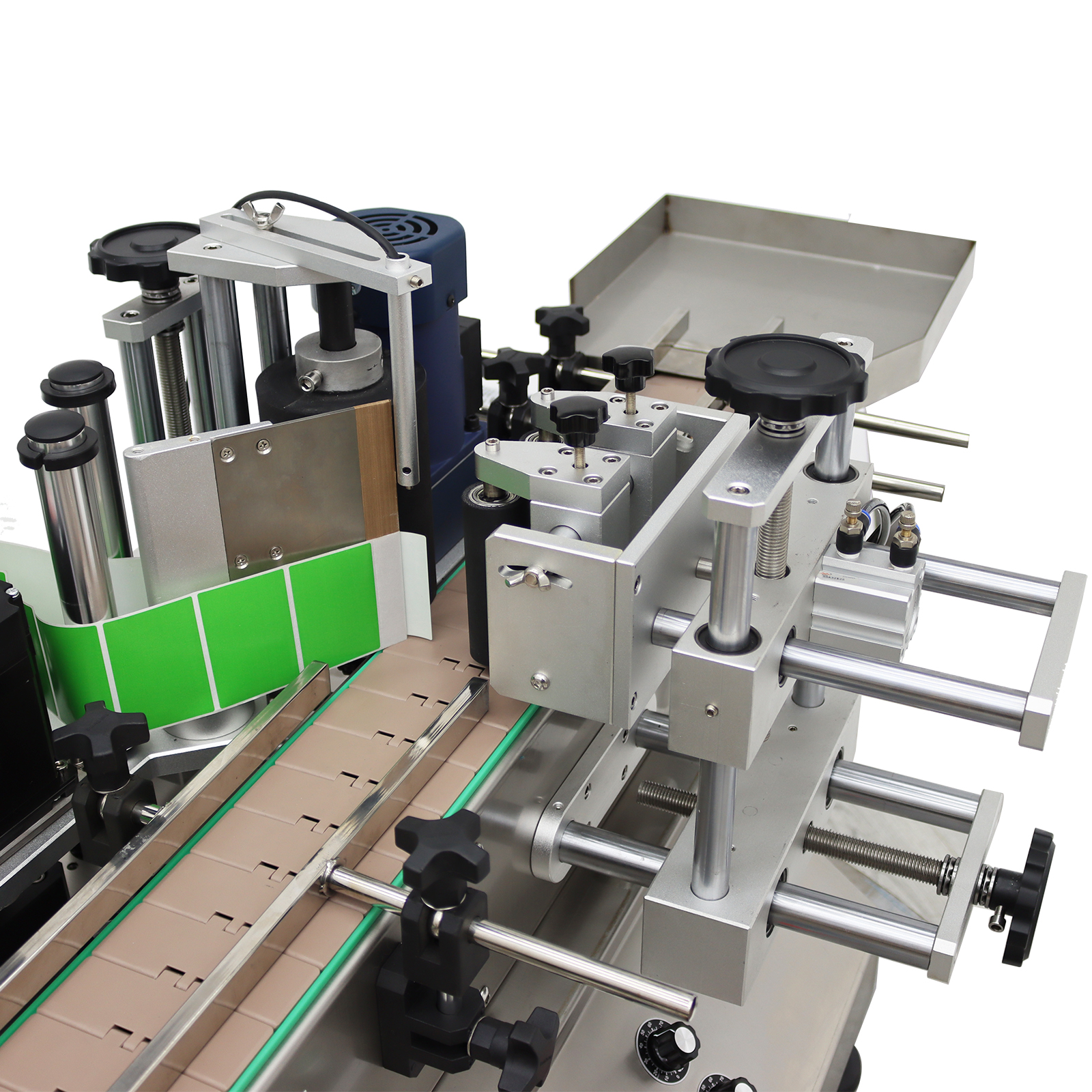

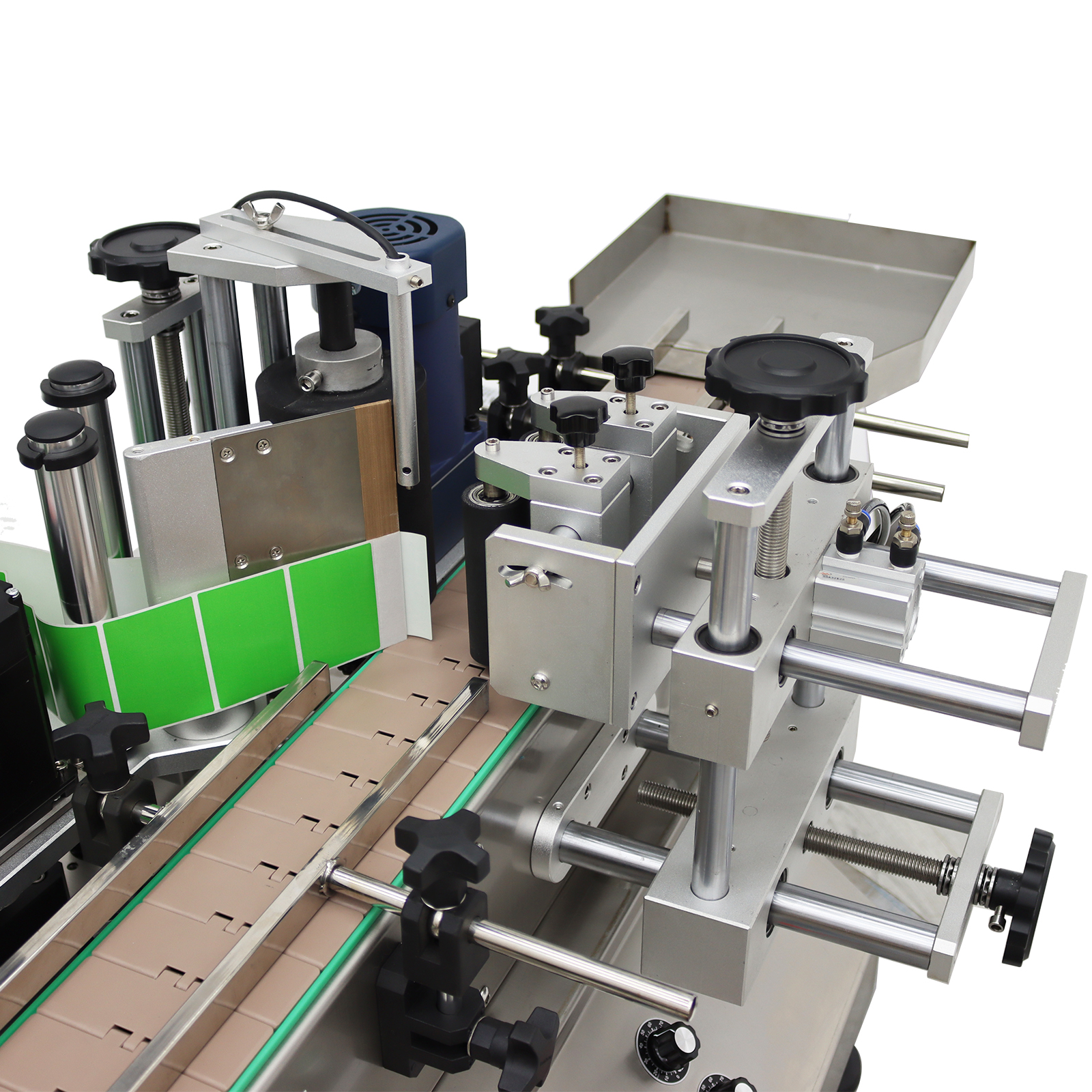

Multi-rod spiral positioning prevents deviation and makes the sheet more accurate. | ||||||||||||||||||||||||||||

|

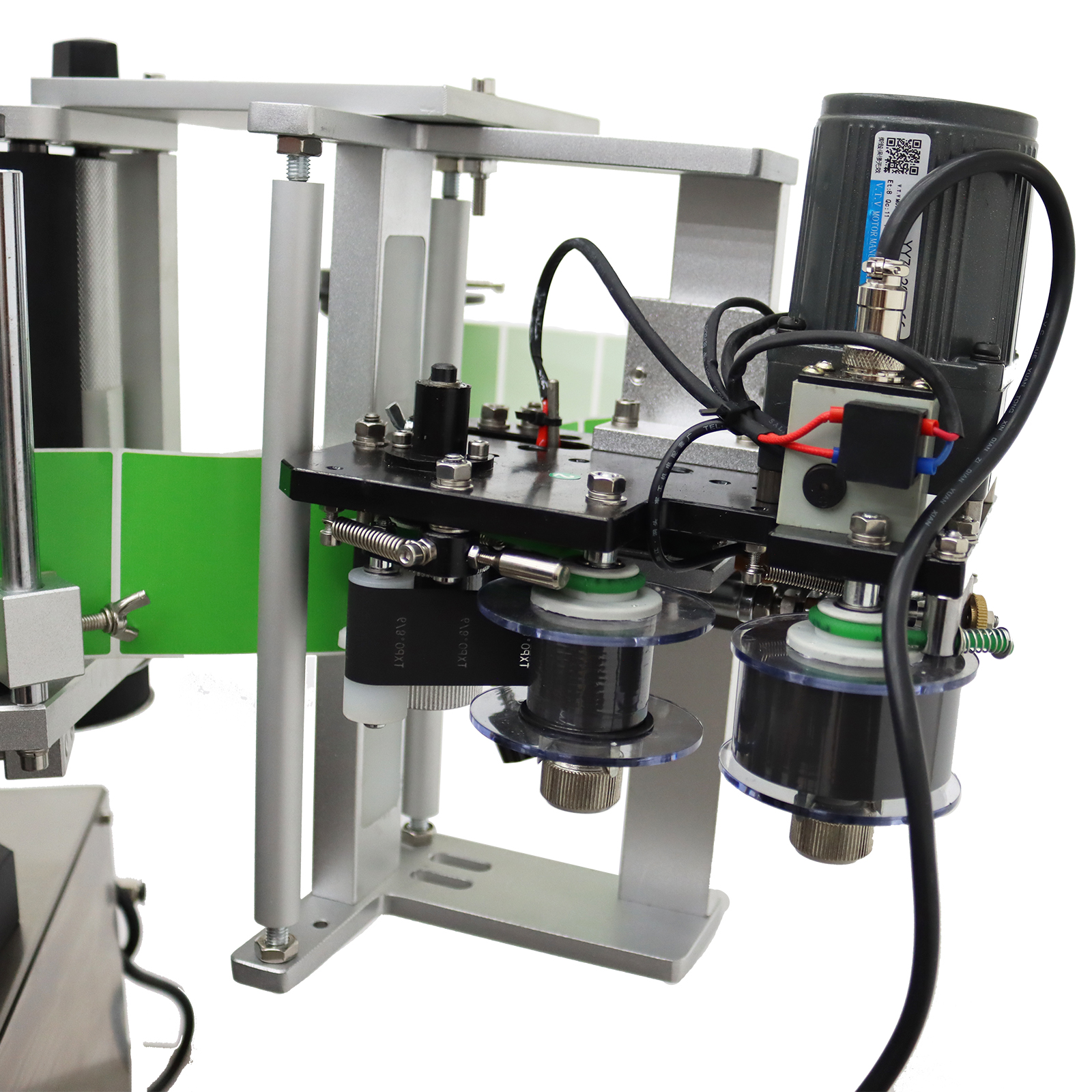

Adding vertex style bottle holding labeling effectively solves the problem of bubbles during the product labeling process. The labeling is flat and wrinkle free, and can be applied. |

|

||||||||||||||||||||||||||||

|

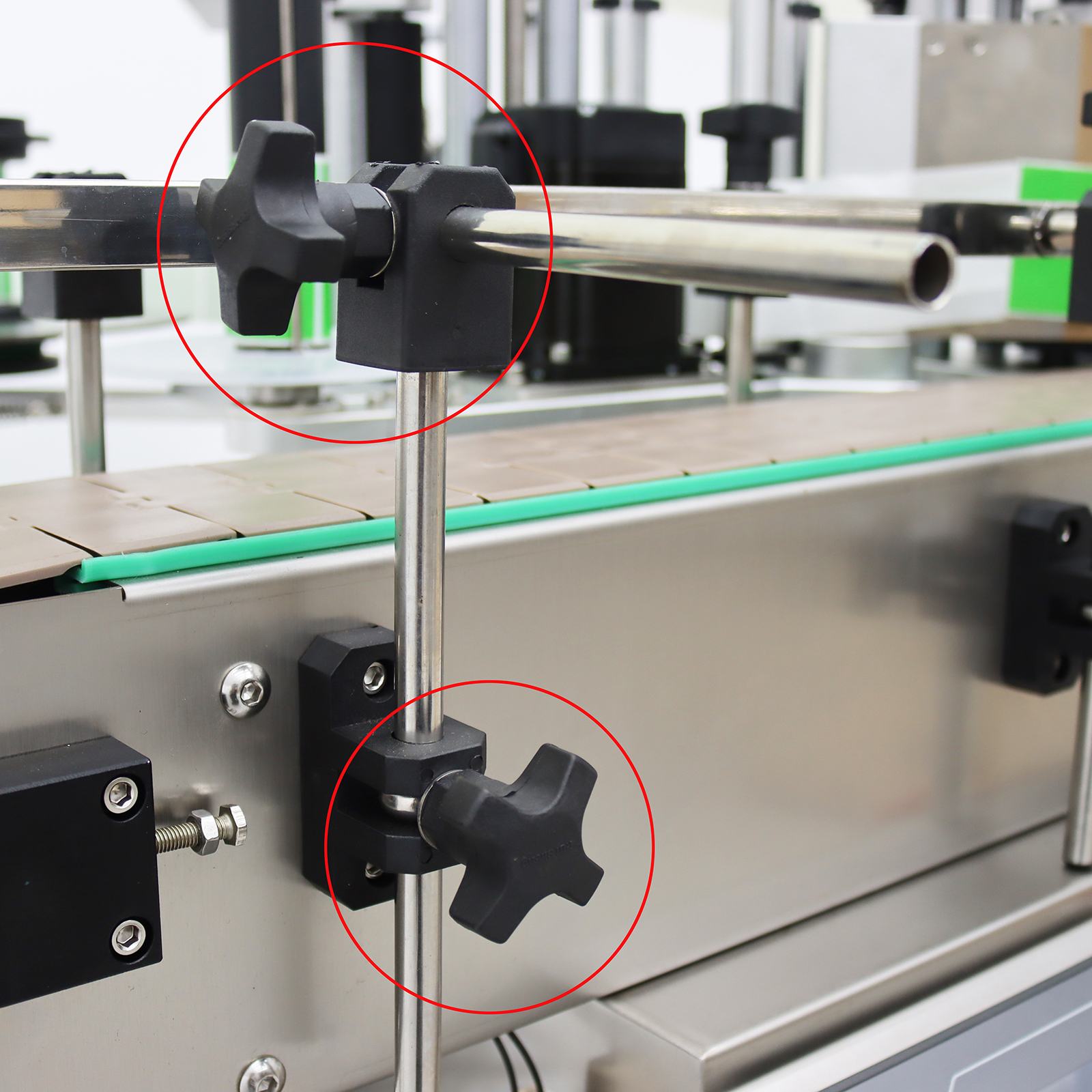

Spoke adjustment handle |

||||||||||||||||||||||||||||

| The label object is sensitive to inspection, and the labeling efficiency is greatly improved.

This is a universal label sensor that can be used to attach both regular and transparent labels, as well as gold and silver transparent labels. |

|

||||||||||||||||||||||||||||

|

|

Photo-electric detection label, and the label will be released immediately when the bottle is detected to pass. | ||||||||||||||||||||||||||||

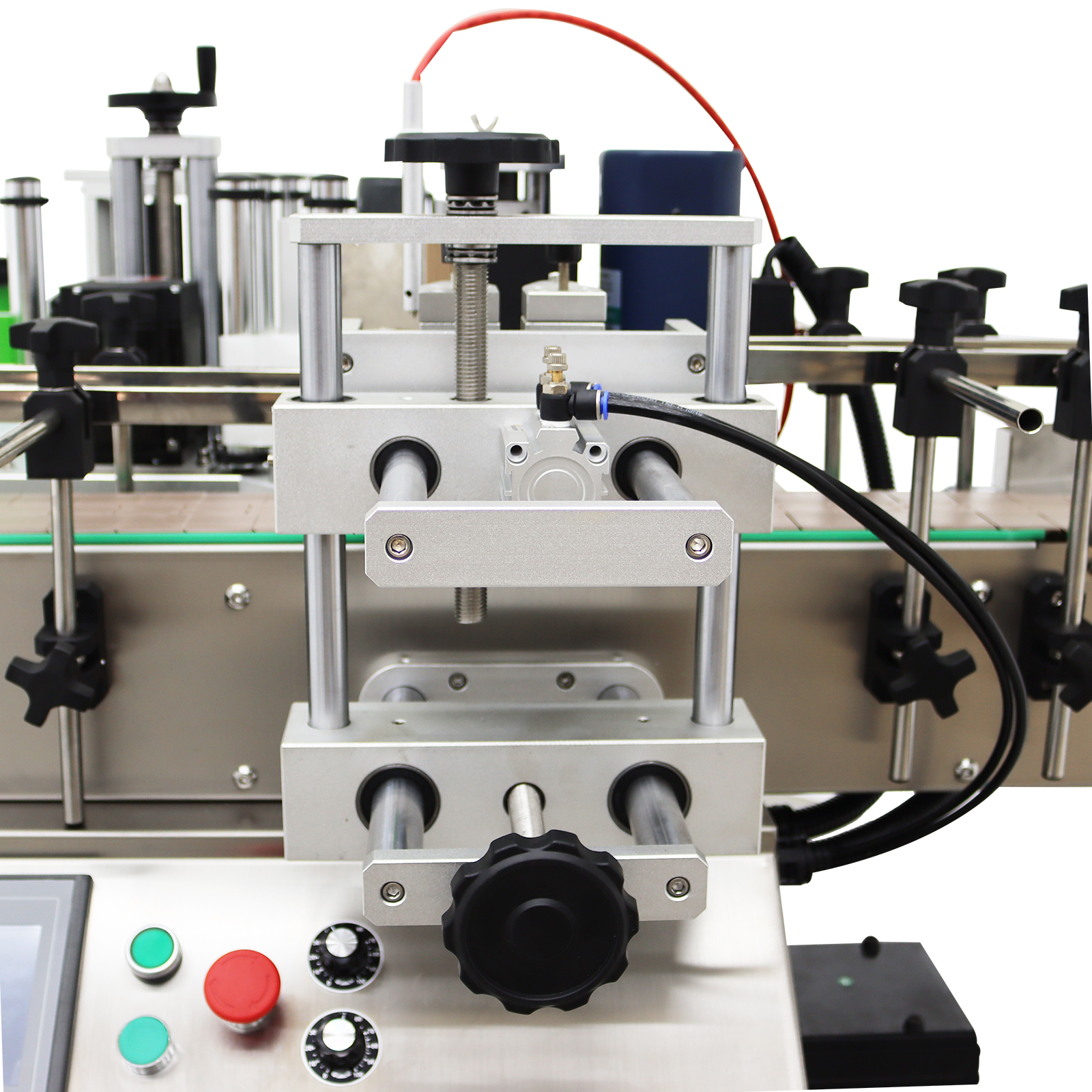

| This machine is equipped with a fiber optic amplifier, which can be adjusted by adjusting the fiber optic amplifier when the photosensitive eye cannot sense the product well. |  |

||||||||||||||||||||||||||||

|

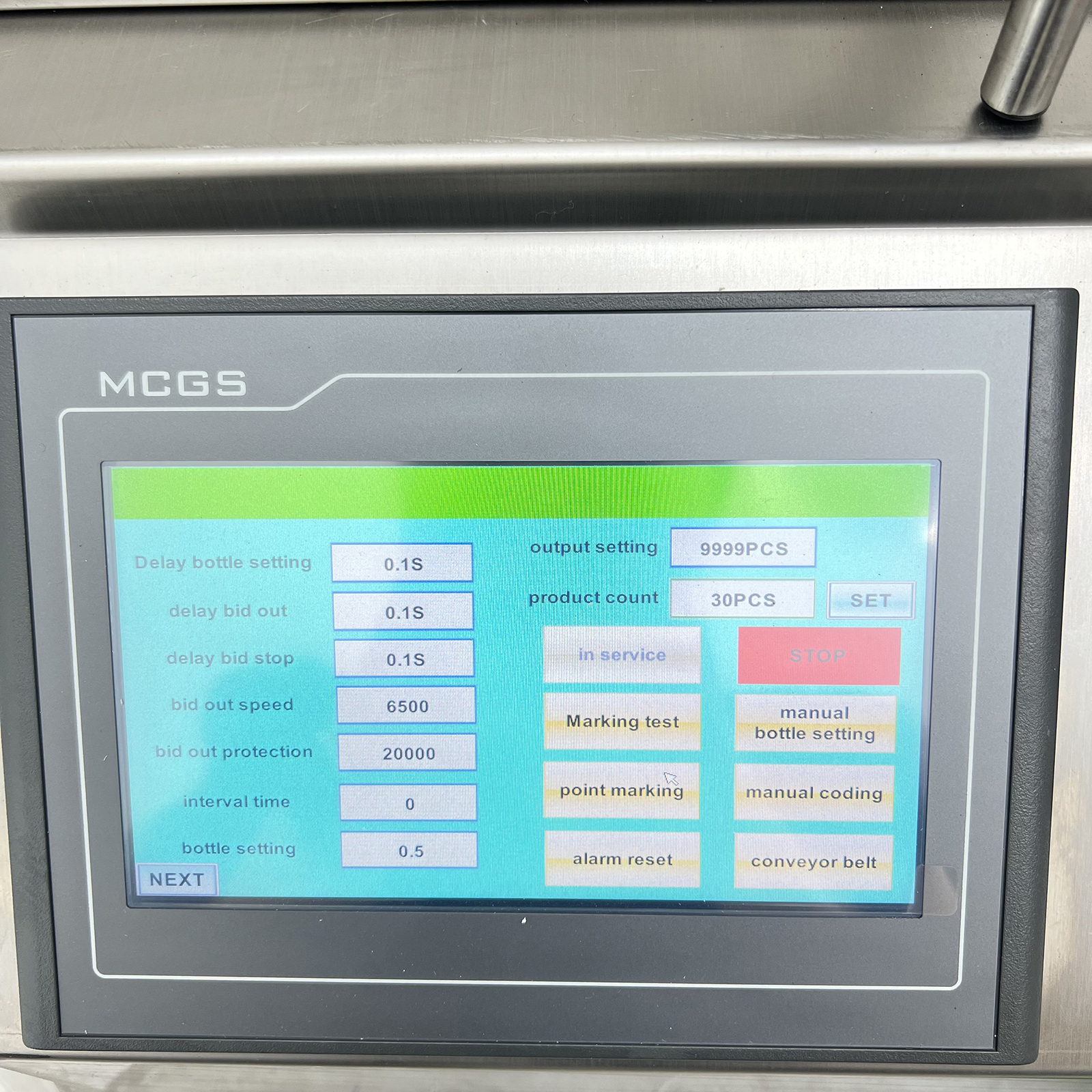

This machine is equipped with a touch screen display, which allows customers to set relevant data according to their needs, making it more convenient and efficient. | ||||||||||||||||||||||||||||

| This machine is equipped with an emergency stop button, which can stop the operation of the machine with one click in case of any emergency, making it safer and more reliable. |  |

||||||||||||||||||||||||||||

|

This machine is equipped with a high-quality conveyor belt motor, which is more durable. | ||||||||||||||||||||||||||||

| This machine is equipped with a chain plate conveyor belt, which is more wear-resistant and has a longer service life. |  |

||||||||||||||||||||||||||||

|

This machine needs to be connected to an air compressor for use (we only provide the machine and do not provide an air compressor, which needs to be purchased by the customer) | ||||||||||||||||||||||||||||

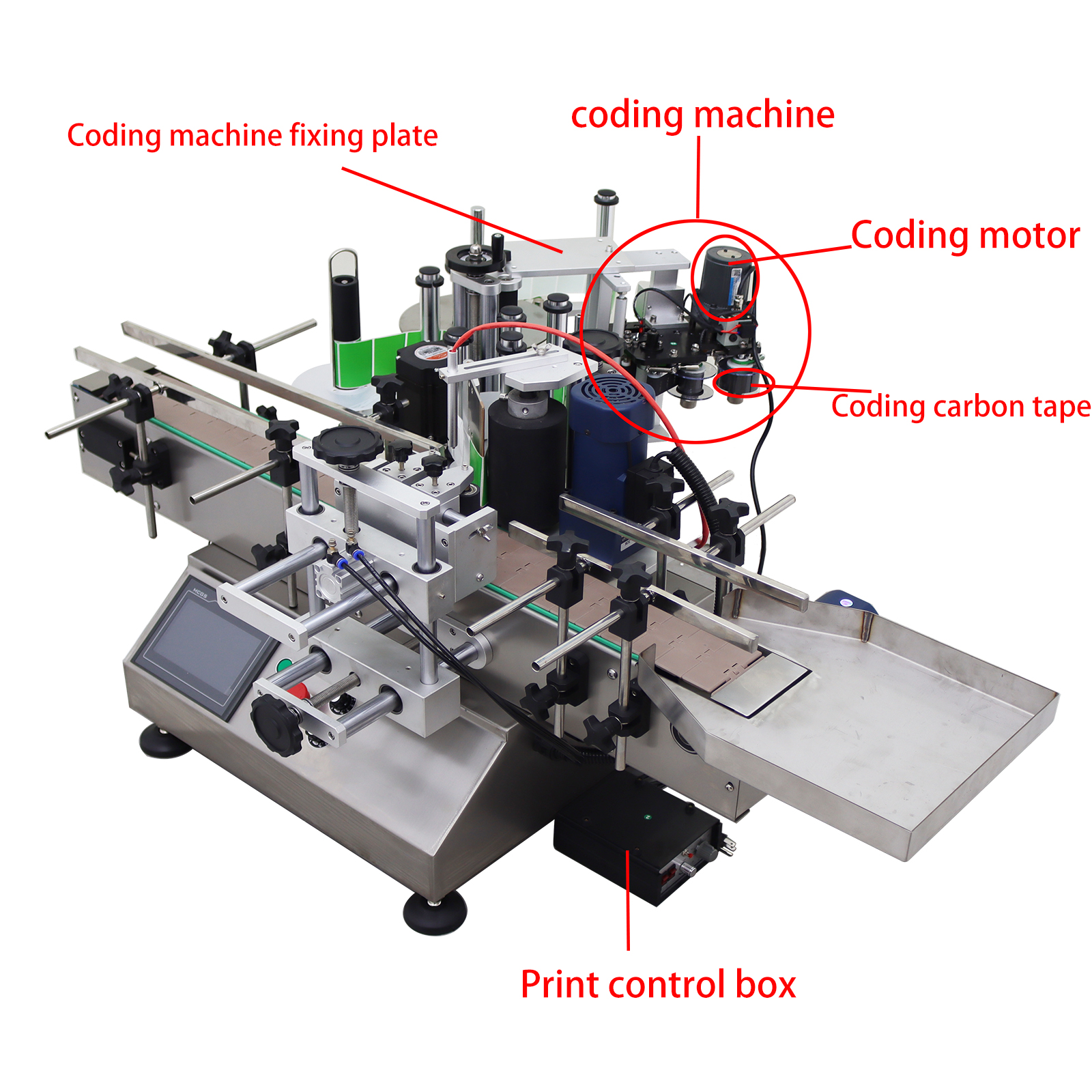

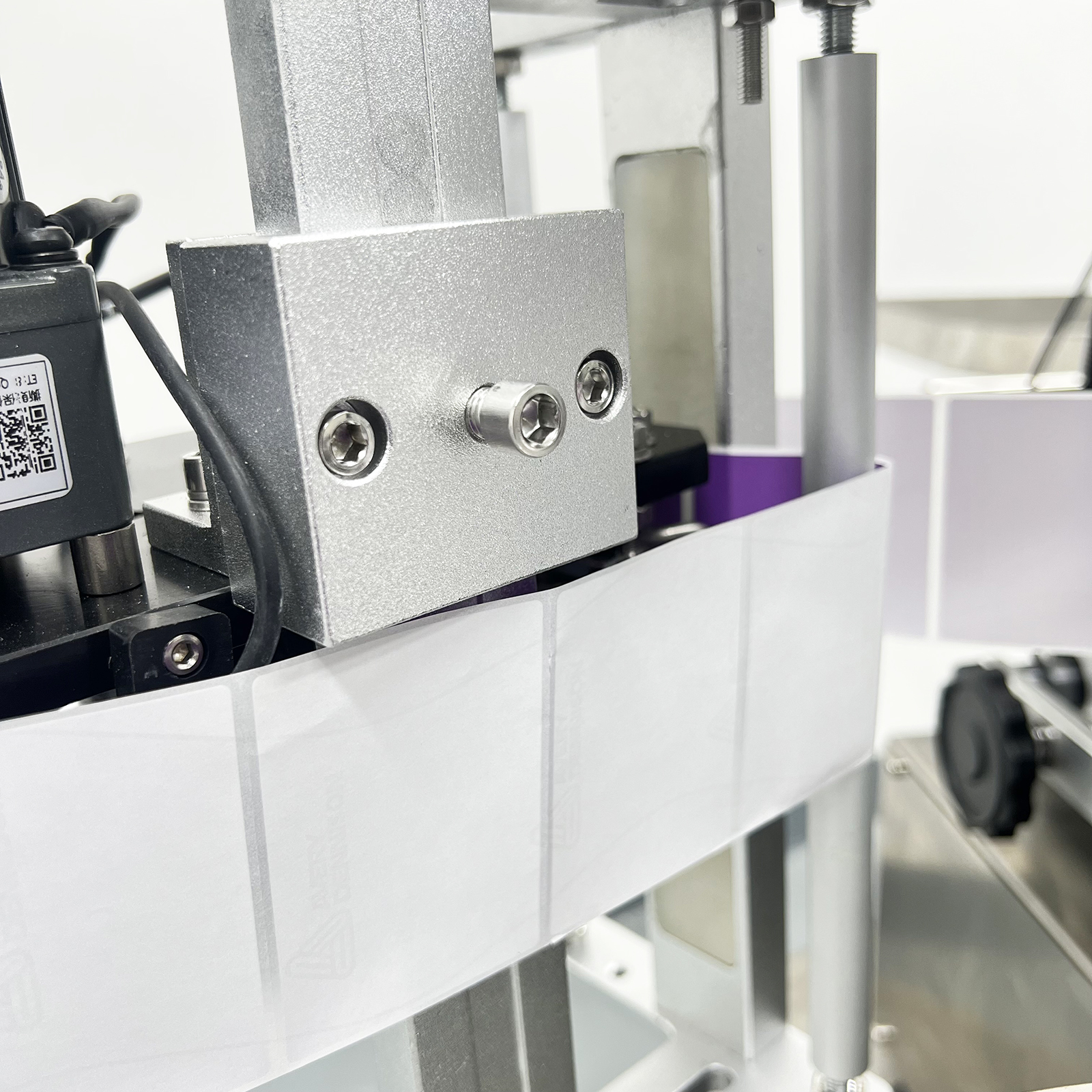

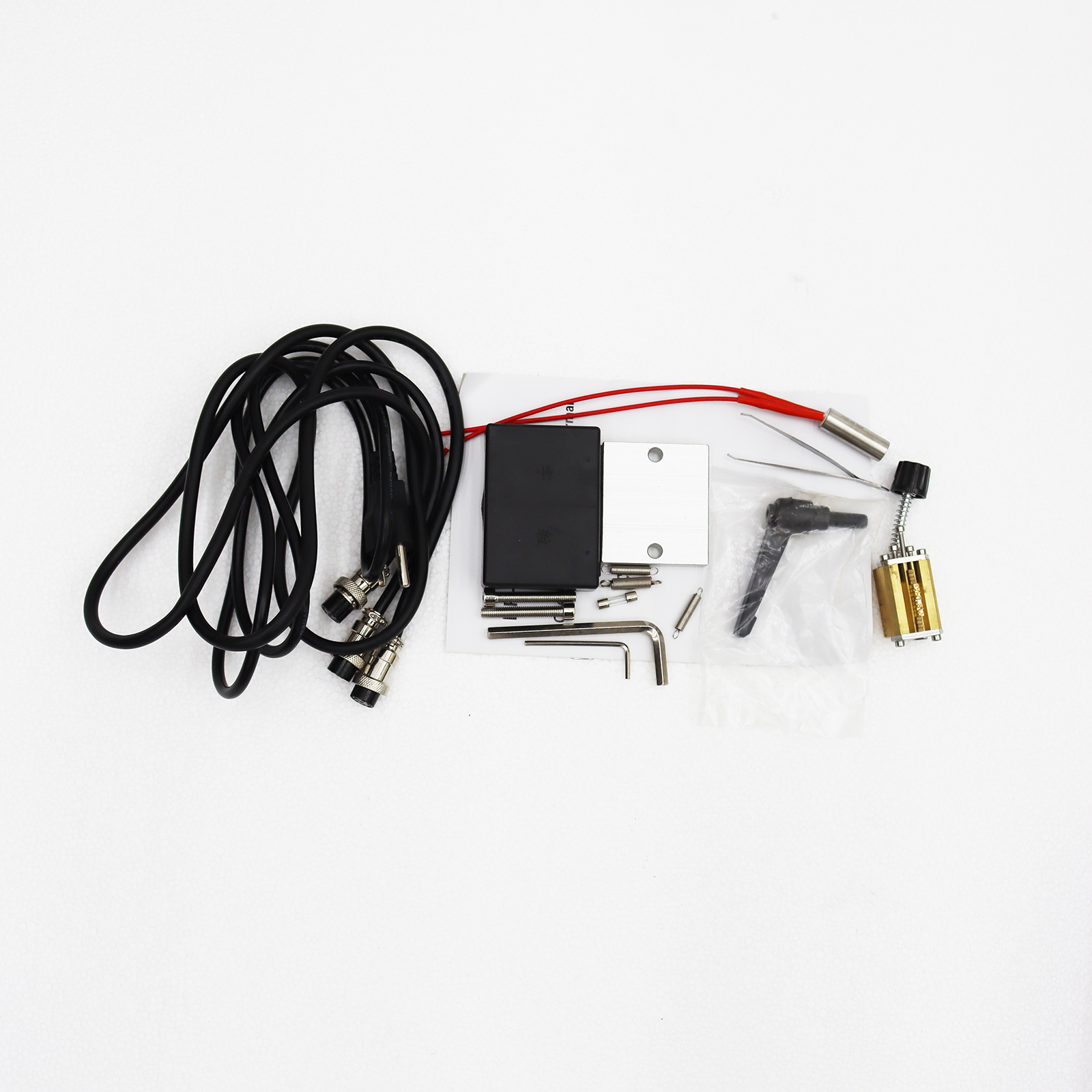

| Print block The word to be printed is placed in the word seat to realize the printing function. (There are only 9 English letters for coding, including exp, lot, and mfg, which are abbreviations for production date, product batch number, and expiration date. There are 5 English letters for each letter, and the numbers 0, 1, and 2 are the same as 5, while the other numbers are the same as 3) |

|

||||||||||||||||||||||||||||

|

|

This machine is equipped with a coding machine, which can achieve coding function. | ||||||||||||||||||||||||||||

| The coding holder is movable as a whole, and can be moved up and down by loosening the screw of this slider, which can help customers find a suitable coding position. |  |

||||||||||||||||||||||||||||

|

After the label is properly positioned, this knob must be in a locked state for the label to function properly. | ||||||||||||||||||||||||||||

| Product safety precautions: | |||||||||||||||||||||||||||||

| To ensure safe production, please read the following precautions carefully: 1. Use the power supply that meets the requirements of the machine. 2. After turning off the power switch, there is still voltage in some circuits in the electrical control of the machine. When servicing the control circuit, be sure to unplug the power cord. 3. Do not touch the rollers with your hands during machine operation, and pay attention to personal safety. 4. When the machine has problems, press the emergency stop button directly to suspend all work. 5.Do not touch the photoelectric induction eye with your hands during machine operation to prevent the machine from missensing and mislabeling.

|

|||||||||||||||||||||||||||||

| Details: | |||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Advantages:

|

|||||||||||||||||||||||||||||

|

1. The machine is efficient and convenient to use; 2. The machine automatically labels, saving manpower and material resources; 3. This machine has wide applicability and stable performance; 4. This machine is equipped with intelligent touch control screen, which is more convenient to set data parameters; 5. This machine can meet the requirements of full-circle labeling or semi-circle labeling of round bottles. The labeling switching between bottles is simple, and the labeling is flat without wrinkles to improve the packaging quality. 6.This machine can be used with capping machine and bottle sorting machine. 7.The components of each adjustment position are precisely matched, and the height, width and width of the components can be easily adjusted without the use of professional tools. The machine operation is simple and simple.

|

|||||||||||||||||||||||||||||

| Product display: | |||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

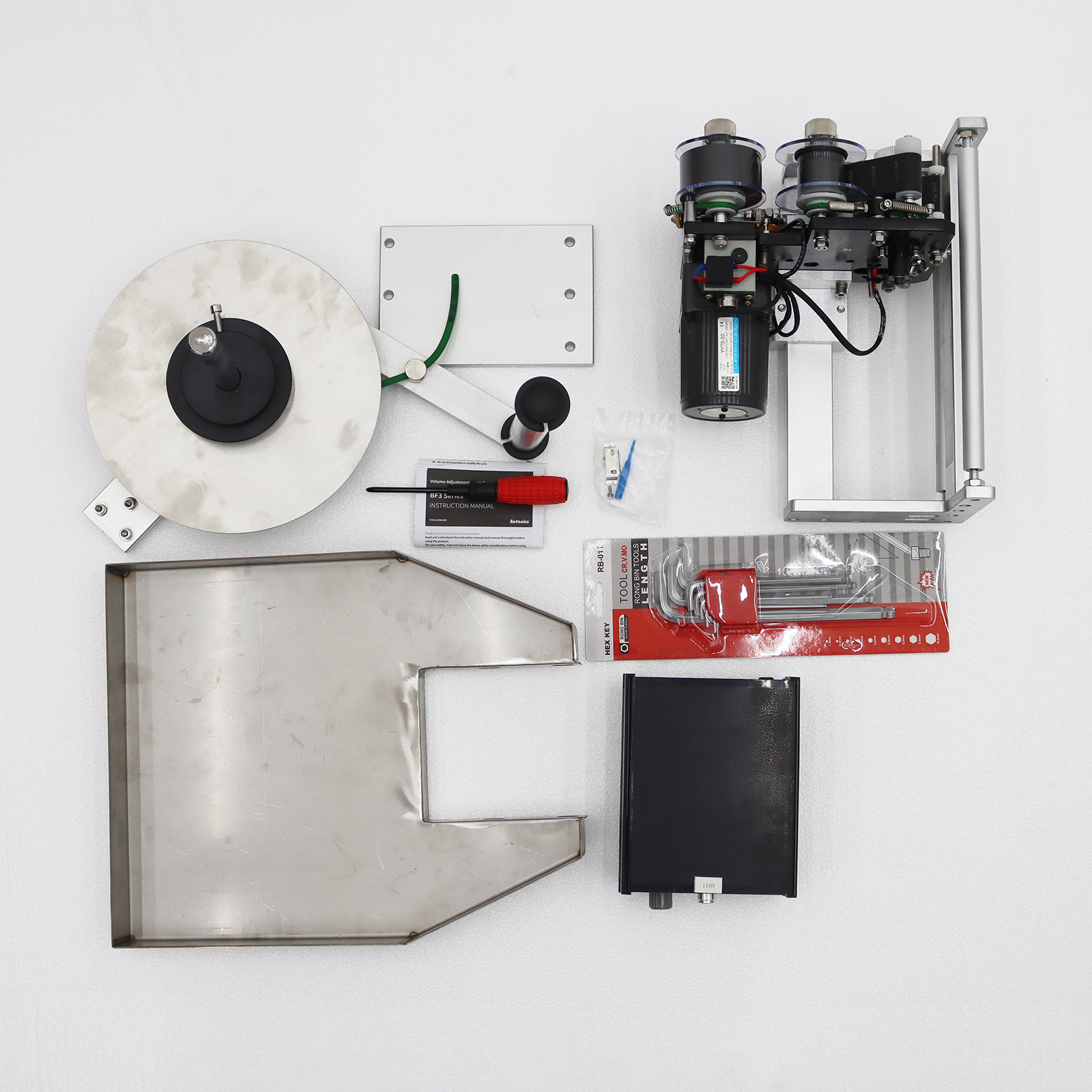

| Item include: LT-150 Fully Automatic Desktop Chain Plate Conveyor Round Bottle Fixed Point High Speed Coding and Labeling Machine*1

|

|||||||||||||||||||||||||||||

| Item Number: 160314 | |||||||||||||||||||||||||||||

|

You can make order with no worry. |

|||||||||||||||||||||||||||||