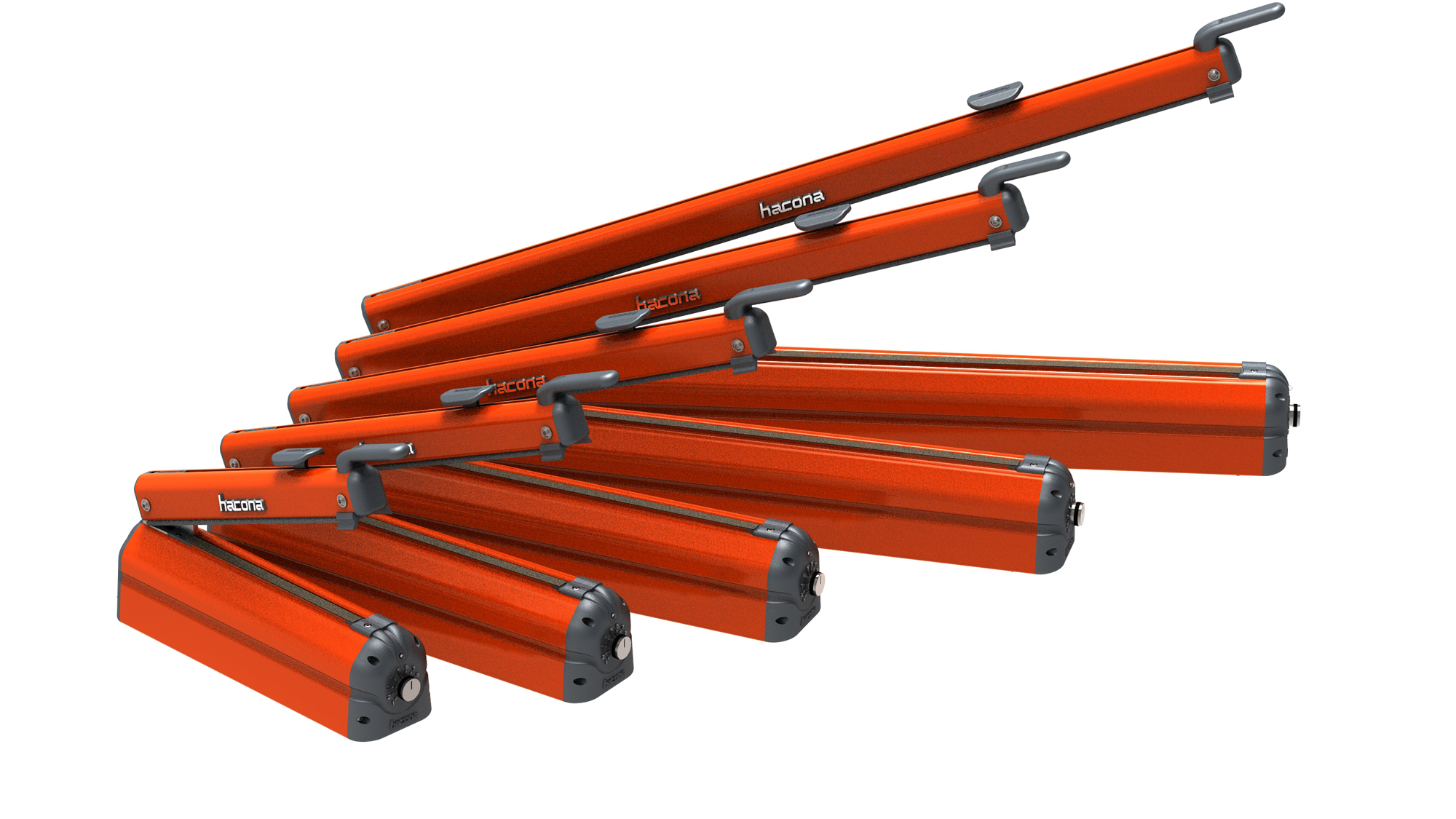

SEALING LENGTH

5 sealing bar sizes assure the maximum flexibility

The hacona C – type impulse heat sealing machines are produced in 5 different sealing bar length. This wide product range assures the maximum flexibility to choose the right machine size for the right application. For small bag sizes the C – 220 impulse film sealing machine offers best place saving solution. If all kind of different bag sizes are used in the packaging, than the C – 820 offers the most flexible solution, because all bag sizes can be sealed on one machine.

Choose the right machine size referring to the biggest bag size used in the packaging process.

All of the C – type impulse film sealing machines are working on impulse sealing principle. The sealing wire gets only hot when sealing bar is closed.

• Maximum safety

• Maximum energy saving

General information: All hacona film sealing machines, including the hacona C – type are designed to seal also narrow packaging films with a wide sealing bar size!

Example: With a C – 820 impulse film sealing machine it is possible to seal very narrow, even 50 mm (2 inches) or 100 mm (4 inches) wide packaging film. No mechanical adjustments are needed to work with 50 mm (2 inches) or even with the 820 mm (32 inches) packaging film.

The sealable maximum material thickness (absolute material thickness) for all C – type impulse film sealing machines is:

PE Polyethilene 200 micron

PP Polypropylene 200 micron

Multi layer - laminated film 100 micron

(depending on the type of the lamination!)

Stepless adjustement of the sealing time with turning knob.

Adjustment possibility from value 1 – 10

All C-type impulse heat sealers – poly bag sealers can be adjusted in sealing time from value 1 - 10. The sealing wire is time controlled. By adjusting the sealing time the temperature will automatically increase in parallel. The sealing temperature can not be set seperatly. It is not possible to adjust the cooling time on the machine. It is suggested to keep the sealing bar min. 1 second longer closed after the red light turns off.

A LED light above the turning knob shows the present status of the impulse heat sealer – poly bag sealer in operation. If the light is off, than the C-type impulse heat sealer is unpluged (the machine is shut OFF). In this condition the machine can be stored or repaired.

By pluging in the machine the LED light will turn yellow. The C-type impulse heat sealer – poly bag sealer is now in standby mode.

The average consumption in standby mode is app. 2 W / hour (electrical power).

To work with the C-type impulse heat sealing machine and to make a sealing the sealing bar has to be closed. The LED light will turn from yellow to red.

Red light shows, that the machine is sealing. After the adjusted time the sealing will stop and the red LED light will turn again yellow.

For perfect sealing result we always suggest keeping the sealing bars closed under pressure for additional 1 – 2 seconds after the sealing is finished (the red light turns back yellow again).